Description

2-Stop Solva Orange-Black Pump Tubing – PT-2010SV

Part Number:

PT-2010SV

Cross Reference(s)

None Available

Detail:

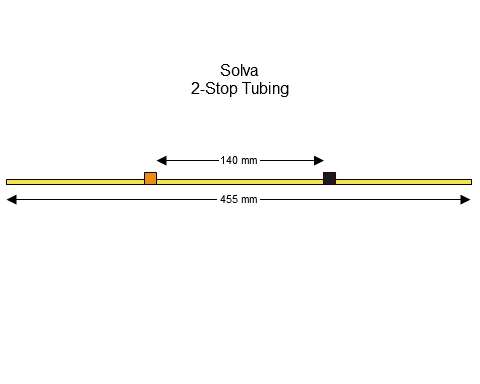

2-Stop Orange/Black , Solva, 0.005″/0.13mm ID., overall length 455mm, 140mm between stops, 12/pkg.

Full Description:

Solva is a type of small bore tubing for various applications. It has a solvent-resistant characteristic allowing it to be used for aromatic oils, solvents, petroleum compounds, inks, and many other applications. Solva tubing is available in standard and flared varieties.

The Unique Characteristics of Solva Pump Tubing

Solva tubing is made from modified polyvinyl chloride (PVC). the following characteristics:

- Solvent-resistant: Solva tubing is resistant to solvents, aromatic oils, petroleum compounds, and inks.

- Phthalate-free: Solva tubing is phthalate-free and meets REACH regulations.

- Low gas permeability: Solva tubing has very low gas permeability.

- Translucent: Solva tubing is translucent, allowing for visual confirmation of flow.

- Bright yellow: Solva tubing is bright yellow; therefore, distinguishing it from standard PVC materials.

Applications for 2-Stop and 3-Stop Solva Pump Tubing

Solva tubing is known for being flexible, translucent, and solvent-resistant. For that reason, it is a staple in many chemical analysis labs for a wide range of applications.

- Peristaltic pumps: Solva tubing is suitable for peristaltic pumps to introduce samples and internal standards into a system, In addition, it is good for removing waste. The tubing ensures a constant flow of liquid, regardless of viscosity differences between the samples.

- Laboratories: Solva tubing is used in pharmaceutical and laboratory applications.

- Industries: Solva tubing is used for industrial applications, such as transporting inks and oils.

When Would You Need Standard vs. Flared Solva Tubing?

A flared tube has an expanded, conical end that creates a flared shape. A flareless tube, on the other hand, does not have this flared end and instead relies on a compression fitting (usually with a ferrule) to create a seal when connecting to another component. Essentially, a flared tube requires a special flaring process before connecting, whereas a flareless tube does not.

Some key factors will help you decide about the type of connection you need. In the flaring process, a flared tube is deliberately expanded at the end to create the conical shape necessary for a proper fit with a flared fitting. Meanwhile, a flareless tube uses a compression fitting with a ferrule that compresses the tube wall to create a seal, eliminating the need for flaring altogether.

When determining which type to use, Keep this basic information in mind. Flared tubes are commonly for applications requiring high-pressure and leak-proof seals. This is especially important in aerospace and hydraulic systems where precise connections are crucial. However, a flareless tube is a top preference for general applications where high vibration resistance is important. And let’s not forget, ease of connection is a big plus with the flareless or standard type of tubing.

Do you have questions? Call Precision Glassblowing to Learn More.

Do you have questions? Visit our FAQs or Technical Information. And, there are several ways to contact Precision Glassblowing. Click here to pick one that works for you