Laboratory glassware is a term that refers to distinct types of glass devices that are used for scientific experiments or measurements. It includes beakers, funnels, flasks, tubes, pipettes, burettes, and many other items. Laboratory glassware is usually made from borosilicate or quartz glass. Both types of materials have high chemical and thermal resistance, low thermal expansion, and increased transparency.

What is Custom, Non-Standard Laboratory Glassware?

Custom, non-standard laboratory glassware is laboratory glassware that is not mass-produced or standardized. Instead, it is designed and manufactured according to the specifications of the customer. It can have different shapes, sizes, capacities, features, or functions than regular laboratory glassware. Typically, it will also offer several benefits for the customer, such as:

Meeting Unique or Complex Requirements

Custom, non-standard laboratory glassware is tailored to fit the exact needs of the customer’s application or experiment. For example, custom glassware will have special dimensions, volumes, markings, fittings, or accessories not available in the standard glassware.

Enhancing Performance or Quality

Custom, non-standard laboratory glassware can improve the performance or quality of a customer’s results or processes. For example, custom glassware will have higher precision, accuracy, durability, or reliability than standard glassware.

Reducing Costs or Risks

Custom, non-standard laboratory glassware can reduce the costs or risks associated with the customer’s work or project. For example, custom glassware can eliminate the need for multiple or redundant pieces of glassware, reduce waste or contamination, or increase safety or efficiency.

Types of Custom, Non-Standard Laboratory Glassware

There are many types of custom, non-standard laboratory glassware that can be made from borosilicate or quartz glass. Some of the common types are:

- Beakers: These are cylindrical containers with a flat bottom and a spout that are used for holding, mixing, heating, or measuring liquids. Custom beakers can have different shapes (such as conical or flat), sizes (from milliliters to liters), graduations (such as metric or imperial), handles (such as plastic or metal), lids (such as screw cap or snap-on), or coatings (such as PTFE or silicone).

- Funnels: These are conical devices with a wide mouth and a narrow stem that transfer liquids from one container to another. Custom funnels can have different shapes (such as pear-shaped or separatory), sizes (from micro to macro), angles (such as 60° or 90°), lengths (such as short stem or long stem), filters (such as paper or mesh), stopcocks (such as Teflon or glass), or adapters (such as ground joint or rubber).

- Flasks: These are round-bottomed containers with narrow necks used for boiling, distilling, storing, or reacting liquids. Custom flasks can have different shapes (such as Erlenmeyer or volumetric), sizes (from milliliters to liters), necks (such as single neck or multi-neck), joints (such as standard taper or ball-and-socket), stoppers (such as rubber or cork), valves (such as needle valve or pressure relief valve), or accessories (such as thermometers or stir bars).

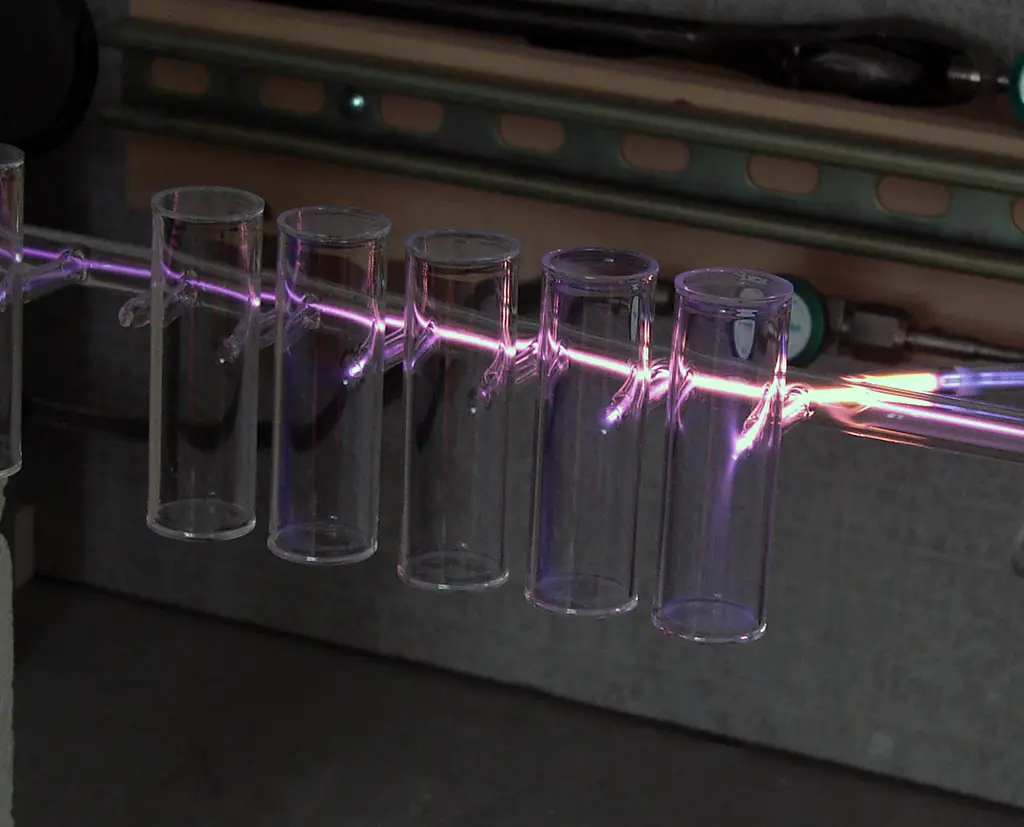

What are small scientific glass tubes called?

Small scientific glass tubes include pipettes, test tubes, and capillary tubes.

Pipettes

- Used to move small amounts of liquids, such as when adding a drop of chemical to a microscope slide

- Can be used to deliver liquids drop-wise or to measure and deliver precise volumes

Test tubes

- Small glass cylinders used to hold, mix, or heat small amounts of chemicals

- Can have round, flat, or conical bottoms

- Culture tubes are a type of test tube used in microbiology labs to grow organisms

Capillary tubes

- Used to determine packed cell volume

- Can be used with or without an anticoagulant to prevent blood from clotting

Choice of Materials and Influencing Factors

A variety of external factors can determine the best materials for custom, non-standard laboratory glassware. For example, these can include the operating temperature and pressure as well as the compatibility with the glass material.

Once all factors have been considered, some of the common materials that are used for the design and manufacturing of custom lab glass are:

Borosilicate Glass

This is a type of glass that contains silica and boron trioxide. It has high chemical and thermal resistance, low thermal expansion, and high transparency. As a result, it is suitable for most laboratory applications that involve heating, cooling, mixing, storing, or measuring.

Quartz Glass

This is a type of glass that contains pure silica. It has extremely high chemical and thermal resistance, exceptionally low thermal expansion, and remarkably high transparency. As a result, it is suitable for laboratory applications that involve elevated temperatures, ultraviolet light, or optical properties.

Suprasil

This is a type of quartz glass that has been purified and refined. It has higher purity, lower impurities, and lower fluorescence than regular quartz glass. Therefore, Suprasil is suitable for laboratory applications that involve high-precision optical measurements or spectroscopy.

Cerium-Doped Quartz

This type of quartz glass has been doped with cerium oxide. It has a higher resistance to solarization, which is the degradation of optical properties due to exposure to ultraviolet light. In this case, it is suitable for laboratory applications that involve long-term exposure to ultraviolet light or high-energy radiation.

Precision ID/OD Tubing and Rod

These are tubes and rods of borosilicate glass, quartz glass, or other materials that have precise inner and outer diameters. As such, they are suitable for laboratory applications that involve fluid flow, pressure, or vacuum.

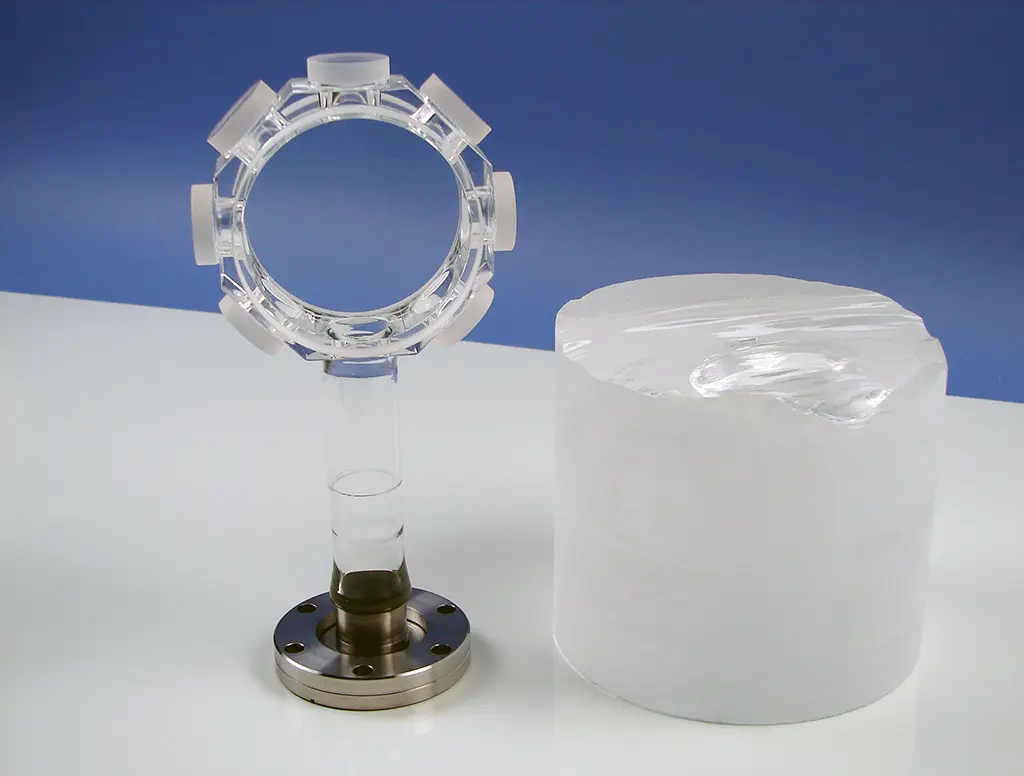

Capabilities of Precision Glassblowing

Custom, non-standard laboratory glassware manufacturing involves various processes and techniques that can produce high-quality and customized glassware. Some of the capabilities and benefits of custom, non-standard laboratory glassware manufacturing at Precision Glassblowing are:

30 + Lathes (Small F to 11″ Bore)

These are machines that can rotate and shape glass tubes or rods into various forms and sizes. They can produce small to large glassware with unique features and functions.

Full In-House Machine Shop

This is a facility that can cut, drill, mill, turn, or weld various materials such as glass, plastics, composites, steel, or aluminum. It can produce complex or intricate glassware components or accessories.

Laser Cutting, Etching, and Drilling

These techniques use a laser beam to cut, etch, or drill holes or patterns on glass surfaces. They can produce precise or detailed glassware designs or markings.

CNC Machining

This is a technique that uses a computer-controlled machine to perform various operations on glass materials. It can produce accurate or consistent glassware shapes or dimensions.

Ultrasonic Milling

This is a technique that uses high-frequency sound waves to create cavities or channels in glass materials. It can produce fine or smooth glassware surfaces or features.

Diamond Cutting

This is a technique that uses a diamond-tipped tool to cut or shape glass materials. It can produce sharp or clean glassware edges or corners.

Sandblasting

This is a technique that uses compressed air and abrasive particles to erode or roughen glass surfaces. It can produce matte or textured glassware finishes or effects.

Centerless Grinding

This technique uses abrasive wheels to remove material from the outer diameter of a glass tube or rod. It produces uniform or smooth glassware diameters or roundness.

Semi-Automated Coiling

This technique uses a machine to bend or coil a glass tube into a spiral shape. It produces flexible or curved glassware tubes or hoses.

Optical Polishing

This technique uses abrasive compounds and pads to smooth or polish glass surfaces. It produces clear or glossy glassware surfaces or optical qualities.

Vacuum Sealing and Silvering

These techniques use vacuum pumps and silver compounds to seal or coat the inside of a glass tube or container. In addition, it produces vacuum-tight or reflective glassware chambers or coatings.

Gas Filling

This technique uses gas cylinders and valves to fill a sealed glass tube or container with a specific gas or mixture of gases. It produces gas-filled or vapor-filled glassware cells or devices.

The Benefits of Custom Work

In the end, custom, non-standard laboratory glassware manufacturing is a fulfilling and satisfying process. That is because it provides the client with:

- Accuracy: Custom laboratory glassware can be manufactured to very precise specifications. This ensures the glassware is accurate and reliable.

- Durability: Custom laboratory glassware is typically made from strong and durable materials. This makes it a desirable choice for applications where the glassware will be subjected to harsh conditions.

- Customization: Custom laboratory glassware can be customized to meet the specific needs of a particular laboratory or research project. This allows for the optimal design and performance of the glassware.

- Safety: Custom laboratory glassware can be designed to meet specific safety requirements. This helps reduce the risk of accidents and injuries.

- Distinctiveness: Custom design produces high-quality, customized glassware products.

- Agile: Doing custom work allows for non-standard planning. Proper planning, and repeat orders, allow for fast, flexible delivery times

- Attractive ROI: Working with a specific contractor to produce custom work, also allows you to negotiate competitive and reasonable prices and terms that suit both parties.

How Can Precision Glassblowing Serve You?

Custom laboratory glassware is a valuable tool for a variety of laboratory and research applications. This type of glassware offers several benefits, including accuracy, durability, customization, and safety. If you’re looking for custom laboratory glassware, we are happy to help you meet your specific needs.

For 41 years Precision Glassblowing has been a manufacturer of laboratory and custom glassware in support of the scientific community worldwide. With the basic concept of what your glassware needs to do, Precision Glassblowing can help design and engineer items made from borosilicate or quartz glass.

While there are many sources for basic laboratory glassware such as beakers, funnels, and flasks, Precision Glassblowing excels at non-standard items, and we possess the capability to produce prototype-to-production quantities cost-effectively. With lathes spanning the range of micro to large diameters and a complete in-house machine shop, we have most of the required tools for every job. If not, we can make them.

How We Work

The items we produce are made from glass tubing, glass plate, ASTM-certified joints, and other specialty fittings produced by some of the top scientific glass manufacturers.

A listing of standard tubing sizes and joint sizes is a suitable place to start when designing your custom glassware. Below are links to this information. We also accept most CAD files once you produce your design. However, we also work from hand-drawn sketches if the complexity does not justify the time involved to produce an official drawing. Unlike metals and plastics, glass behaves differently so various design features may require slight modification to ensure they can be manufactured and aren’t prone to breakage after receipt.

For more information or questions, contact us.