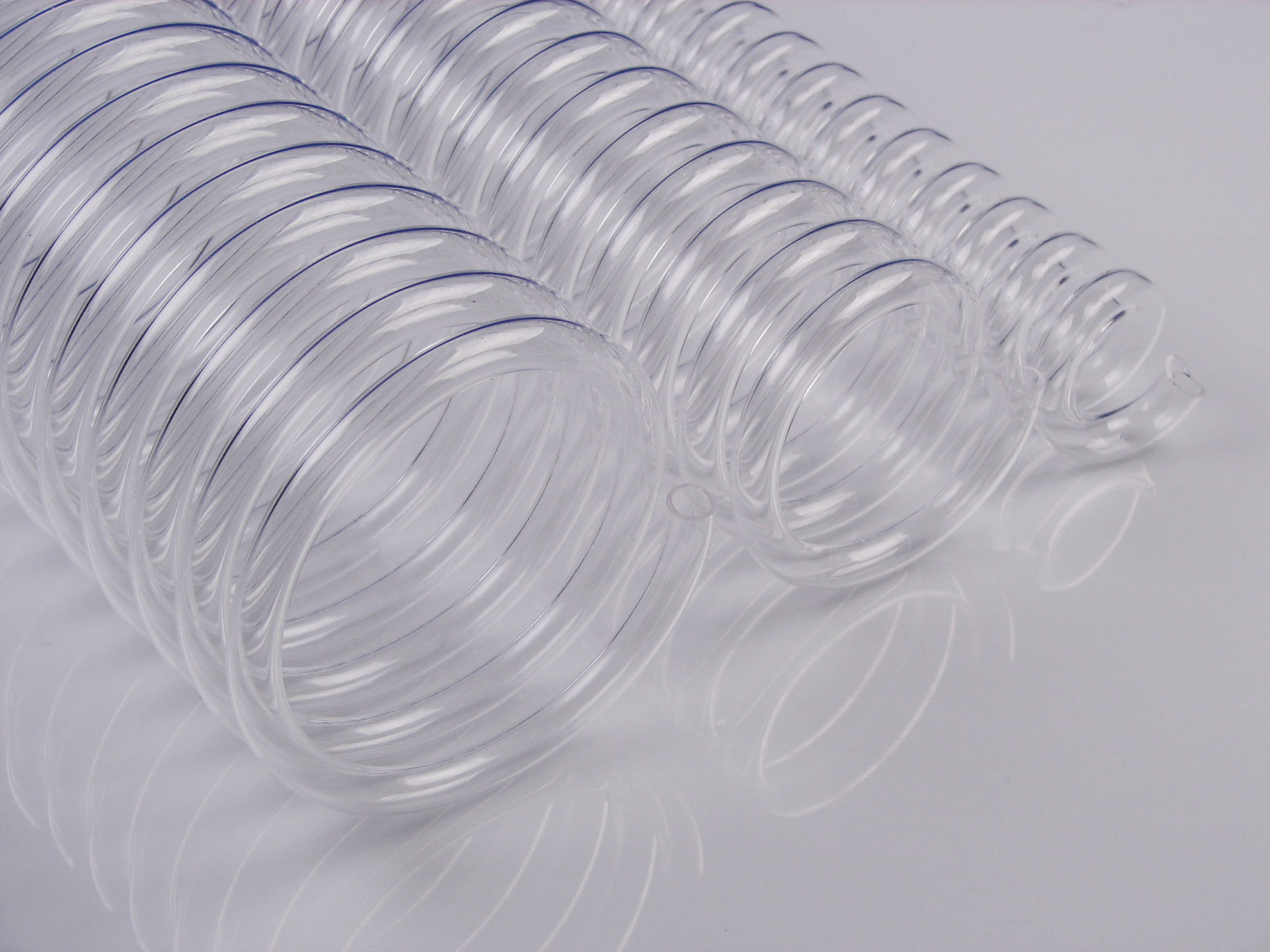

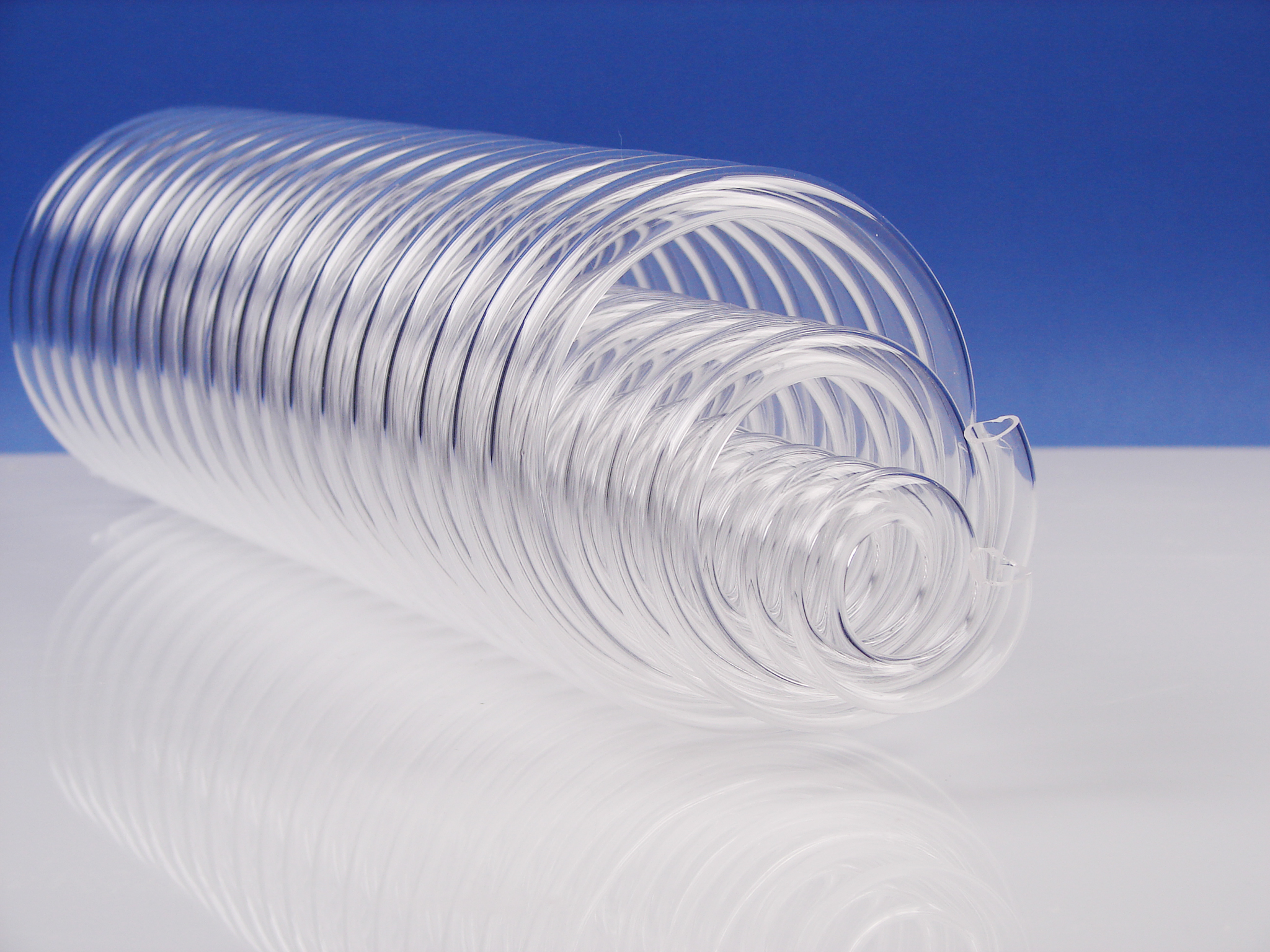

What is a custom glass coil? A custom glass coil is a special design, craft glass tube in a coil of various shapes and sizes that meets specific requirements for applications like heating, cooling, distilling, or mixing. They feature precision-engineering for use in scientific, industrial, and decorative contexts, and are from materials like borosilicate glass or quartz to ensure durability, chemical resistance, and thermal stability.

- Customization: Unlike standard, off-the-shelf components, custom coils are made to exact specifications. Therefore, they can vary in specific dimensions, shapes, and volumes.

- Materials: They can be made from a variety of glass types. Some examples are borosilicate glass, known for its chemical resistance and thermal shock stability, or quartz glass, often used for high temperatures, purity, and UV applications.

- Purpose: They serve a variety of functions, including:

- Condensing and distilling: Employed in separation and purification processes.

- Mixing: Used to blend reagents in a controlled manner.

- Heat transfer: Used as heating or cooling systems in scientific or industrial processes.

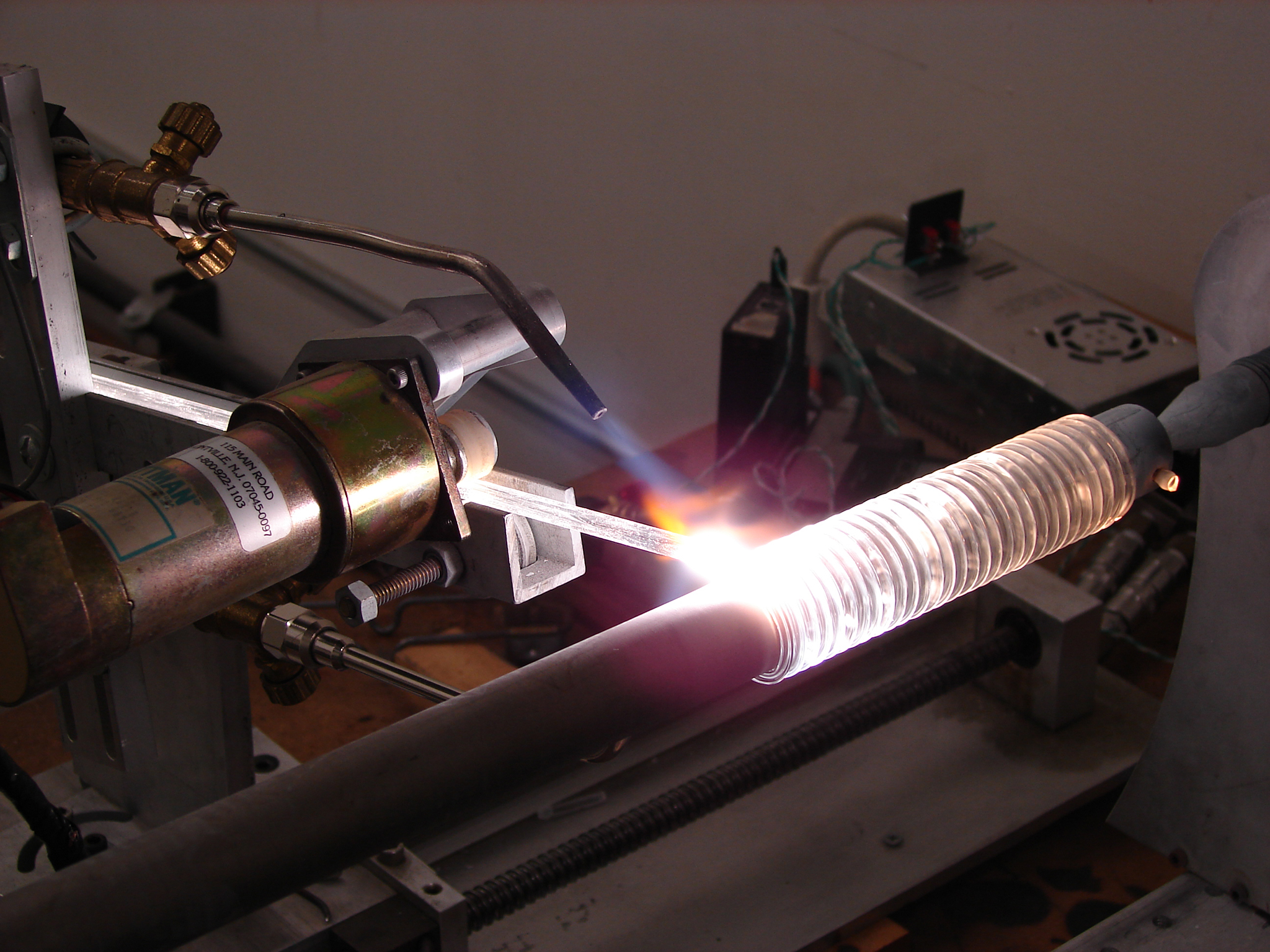

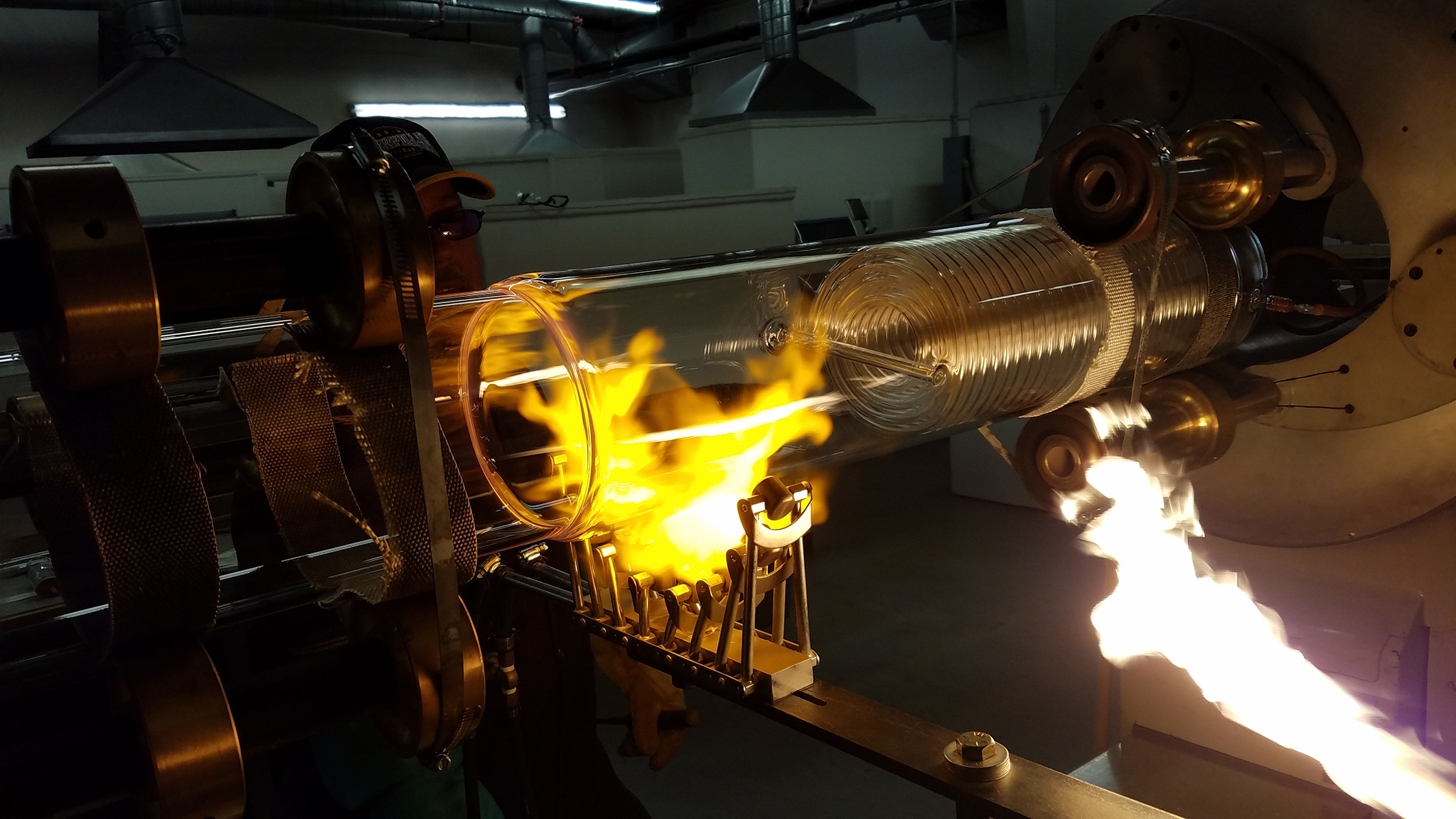

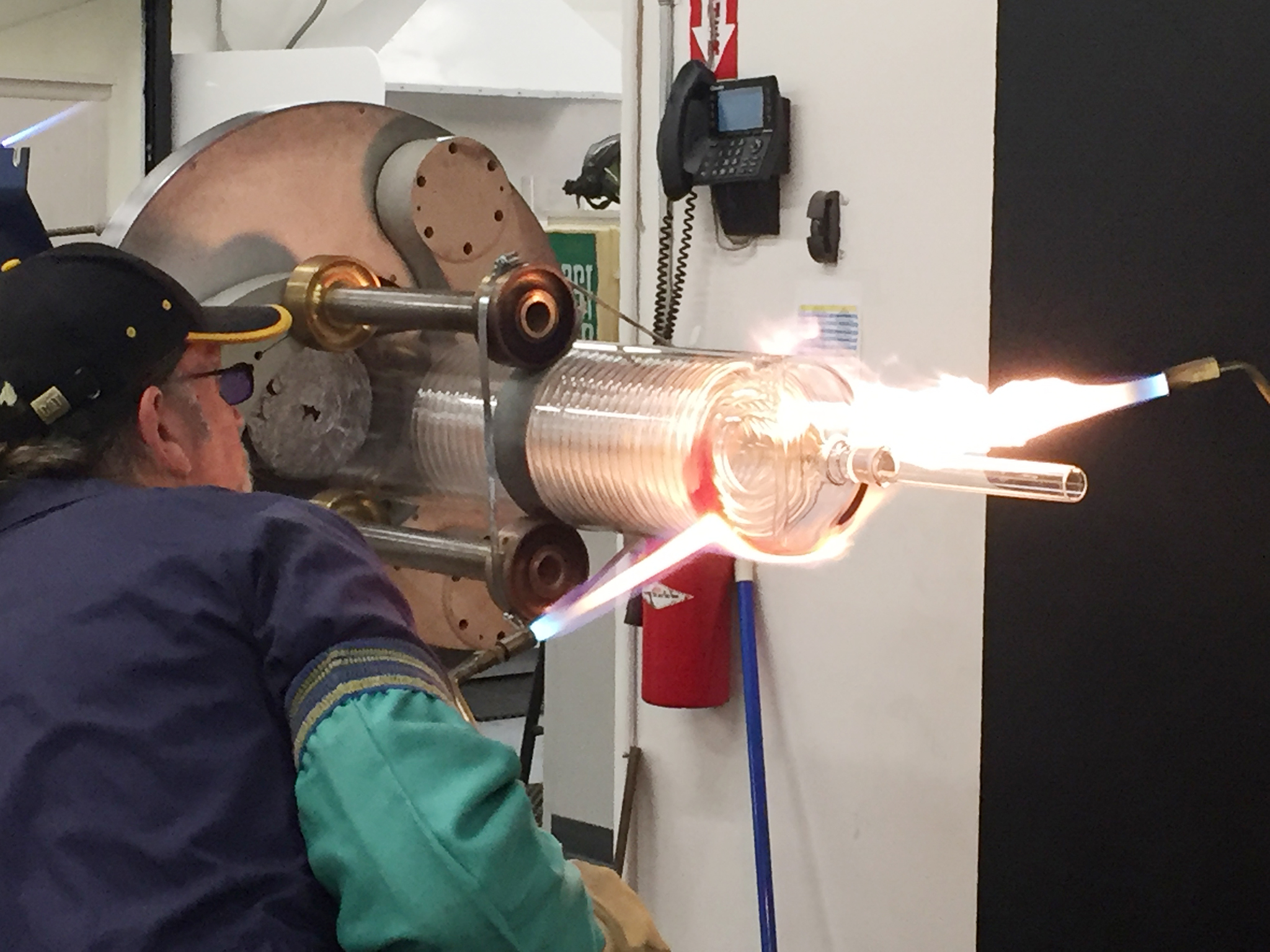

- Precision Manufacturing: Custom glass coils use precise techniques, often involving machines that coil glass tubes into spiral or helical shapes.

- Applications: Custom coils are useful in a wide range of industries, such as pharmaceuticals, chemistry, food processing, and more, where standard equipment is not suitable.

What are the Benefits of Custom Glass Coils?

Glass coils are often custom to improve performance, to fit specific equipment, and to handle unique requirements like high temperatures or tight spaces. Customization offers a more efficient, durable, and precise solution than standard options. This makes them essential for special applications in fields like chemical processing, scientific research, and industrial manufacturing.

1. Performance and Precision

- Optimize efficiency: Custom designs, like a specific coil shape or size, can maximize heat transfer, fluid flow, or chemical reactions for a particular application.

- Special function: Custom design can handle specific conditions. This includes, for example, extreme temperatures, pressures, or corrosive environments that standard parts might not withstand.

- Enhanced precision: Customization allows for a perfect fit. As a result, it prevents leaks and ensures accurate results in scientific experiments or industrial processes.

2. Flexibility and Compatibility

- Custom fit: Custom coils can fit specific, unique spaces. In fact, they can also replace hard-to-find parts in existing equipment.

- Design Flexibility: Custom glass coils can allow for the development and testing of innovative solutions, which is crucial for scientific research and the creation of new technologies.

- Easy Maintenance: Custom designs enable easy assembly and disassembly, which streamlines cleaning and repairs.

3. Durability and Safety

- Increased durability: Custom coils with higher-quality materials are more resistant to abrasion, corrosion, and impact, leading to a longer lifespan.

- Reduced risk: Customization in clean environments helps reduce the risk of contamination, especially for sensitive materials.

- Material integrity: Custom Coils can be non-toxic and non-reactive. Therefore, this makes them a safe choice for many chemical and industrial processes.

Making the Transition to Custom Glass Coils

Making the transition to custom glass coils involves a structured process of vendor selection, design collaboration, and implementation to ensure the final product meets your exact performance requirements. Partnering with an experienced manufacturer offers benefits such as special expertise, higher quality control, and potential cost savings through process optimization.

Phase 1: Vendor Selection and Partnership

The most critical step is selecting the right manufacturing partner. Look beyond a simple supplier to a company that functions as a strategic partner, such as Precision Glassblowing of Colorado, that is invested in your long-term success.

- Assess Experience and Expertise: Look for a vendor with a proven track record in manufacturing custom glass coils and, when possible, specific experience within your industry (e.g., pharmaceutical, chemical, or research).

- Evaluate Quality Control & Certifications: Ensure the vendor adheres to strict quality standards and possesses relevant certifications (like ISO 9001). Ask about their inspection procedures, error rates, and how they address defects.

- Check Capabilities and Flexibility: A good partner offers a range of in-house services (turnkey solutions) from design to testing and can handle both prototyping and high-volume production. They should be flexible enough to accommodate your specific design changes and production timelines.

- Prioritize Communication and Collaboration: A healthy partnership requires clear communication channels, dedicated points of contact, and a willingness to engage in early design phases to ensure a smooth transition.

- Review Cost and Total Value: While cost is a factor, focus on the total project costs and long-term value, not just the initial price per piece. An experienced partner can often suggest design improvements that enhance quality and reduce costs in the long run.

Phase 2: Design and Prototyping

Once you select a partner, the transition moves to the design and development stage.

- Define Requirements: Work closely with the vendor’s engineering team to clearly define all performance requirements, including material selection (e.g., borosilicate or quartz glass), dimensions, temperature/pressure resistance, and chemical compatibility.

- Collaborative Design: The vendor should use their expertise to come up with new ideas, provide “design for manufacturability” (DFM) analysis, and create technical drawings with detail.

- Prototyping and Testing: Prototypes are crucial for ensuring the design meets objectives and validating the design for production manufacturability. The vendor should provide support for testing and make necessary design adjustments pending results.

Phase 3: Production and Ongoing Support

The final phase involves scaling up production and maintaining the partnership.

- Process Optimization: The vendor will optimize the manufacturing process for efficiency and consistency. This is done using skilled glassblowers and specific tools to shape the coils to specification.

- Supply Chain Integration: Coordinate material sourcing and logistics to ensure a streamlined supply chain, which might involve redirecting raw materials from your existing suppliers to the new vendor.

- Production Release and Support: Once the design is finalized and tested, the vendor can transition to full production. A good partner will offer ongoing technical support and act as a resource for future needs.

You can learn more about custom glass coils by contacting Precision Glassblowing through our contact form, by email, or by phone.