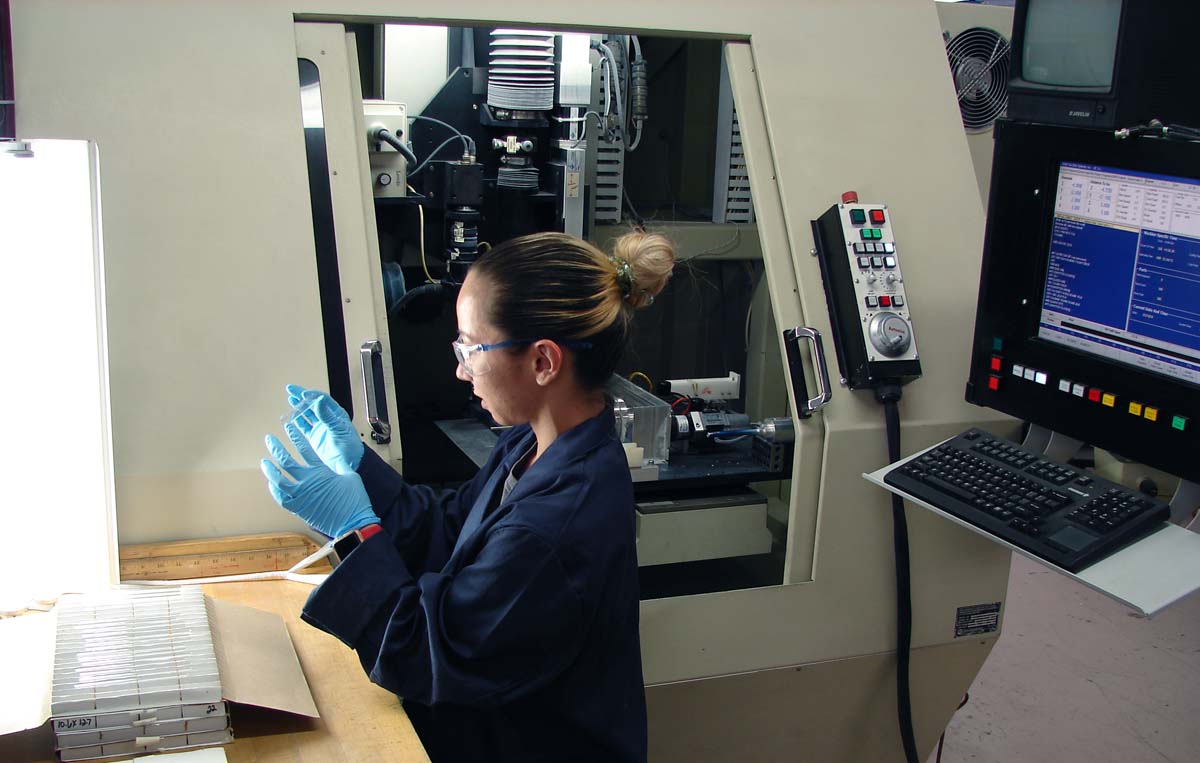

Laser processing at Precision Glassblowing helps us in many aspects of glass manufacturing besides the obvious cutting, scoring, and marking of various glass types. It perfectly suits the high-performance glass used in technical and scientific applications.

This non-contact method reduces concerns about cracks or stress from mechanical processes. Requiring no consumables and with high repeatability, it’s an efficient choice.

Ensuring Smooth Finishes

Controlling the laser processing system precisely is crucial for a smooth cut finish, protecting the glass’s integrity. Marks are also controlled to ensure a consistent finish without chipping or flaking.

Leading Change with Lasers

Precision Glassblowing processes glass types like Sapphire, Borosilicate, Quartz, and Soda Lime. The choice of laser depends on the material and desired results. Pulsed and ultrashort pulsed lasers are popular for ensuring proper edge effects, consistent mark contrast, and minimal heat impact. Beam delivery options include scan heads for high-speed marking or cut heads for smaller spot sizes in cutting.

The Cutting Edge in Tools

Our team uses lasers for various tasks on the glass we manufacture. We study glass manipulation to determine which tasks lasers can perform better than other technologies. Laser manipulation of glass is a precise, contactless process. It can handle everything from cutting to drilling to welding glass.

Precision Glassblowing Laser Processing Technologies

In addition, lasers are useful for cutting thin glass sheets and chemically strengthened glass. Both are difficult to cut mechanically. Laser cutting happens almost instantaneously, preventing the glass from reacting as it would with mechanical cutting. This allows for more shaping options, including curvatures and design variations.

Laser Processing Drilling Precision

Laser drilling offers greater precision than mechanical methods. Precision is essential when creating millions of perforations in glass wafers for semiconductors. Lasers can achieve micron-level accuracy, which is impossible with mechanical processes.

Minimal Maintenance and High Automation

Lasers require minimal maintenance or replacement. Mechanical parts can wear down or break, leading to inconsistency. Lasers, however, do not contact the glass directly, ensuring consistent performance. They are also highly automated, running constantly with little supervision and processing glass faster.

Laser Impact on the Glass Manufacturing Industry

Laser technologies add value to glass production. Mechanical processes are reaching their limits for many glass products. Precision cutting, drilling, coating, melting, and texturing of advanced specialized glass are now performed by lasers. Due to their low maintenance and cost-efficiency, the glass industry now relies on lasers for modern production.

Ultra-Thin Glass Processing with Lasers

Lasers are essential for processing ultra-thin glass that cannot be cut mechanically. For example, lasers can improve mobile reception inside buildings by breaking up coated insulating glass units. It does so by making fine patterns without altering the appearance of the glass. Of course, this would be impossible to do mechanically.

Sustainability Metrics Improve with Lasers

Lasers enable thermal processes, heating glass coatings to high temperatures without affecting the glass. This is particularly beneficial for processing thermally tempered glass. Using laser technology helps save CO2 and, with alternative energies, can eliminate its use. There is no need for energy-intensive treatment of process water or producing high-wear cutting and separation equipment.

Precision Glassblowing’s Expertise in Optical Physics

Lasers are integral to Precision Glassblowing’s work in optical physics. The interactions between light and materials are central to our glass technologies. By working with lasers, we turn the properties of light into an asset, enhancing our capabilities and innovations.