ICP-MS, aka Inductively coupled plasma mass spectrometry, is a powerful analytical technique that detects and quantifies trace elements in various samples. As such, this method combines a high-temperature plasma source with a mass spectrometer to ionize the sample and measure the ions produced. ICP-MS is known for its sensitivity, precision, and ability to simultaneously analyze a wide range of elements.

How ICP-MS Works

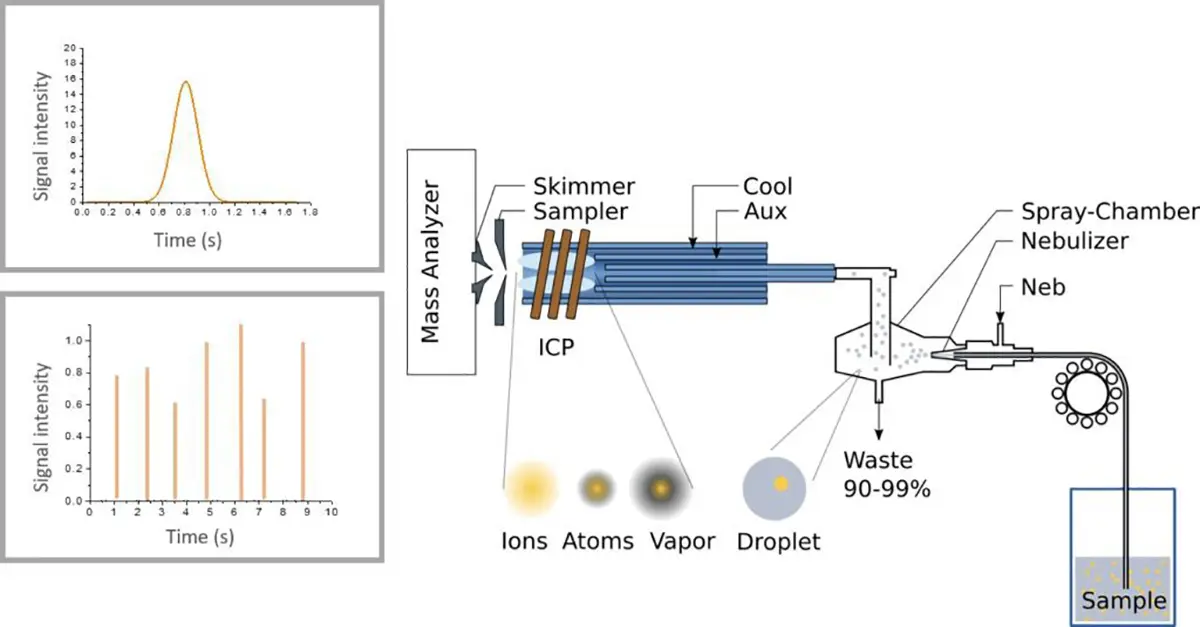

ICP-MS operates by introducing a sample into a plasma torch, where it’s ionized at temperatures exceeding 6,000°C. The ions generated are then directed into a mass spectrometer, which separates them based on their mass-to-charge ratio. This process allows for the detection of elements at concentrations as low as parts per trillion.

The System Overview

An ICP-MS system comprises numerous key components that work together to analyze samples. We will take a closer look at these components later in this article. Here are the six fundamental compartments of a single quadrupole ICP-MS:

- Sample Introduction System: This includes a nebulizer for aerosol generation and a spray chamber for droplet selection.

- Inductively Coupled Plasma (ICP): The plasma torch generates the high-temperature plasma needed to ionize the sample.

- Interface: This compartment transfers the ions from the plasma into the mass spectrometer.

- Ion Optics: These components focus and direct the ions towards the mass analyzer.

- Mass Analyzer: This separates the ions based on their mass-to-charge ratio.

- Detector: This detects and quantifies the ions.

Applications of ICP-MS

ICP-MS is widely used in various fields, including environmental monitoring, food safety, pharmaceuticals, and geochemistry. It plays a crucial role in detecting contaminants in water, analyzing the nutritional content in food, and studying geological samples. The versatility and accuracy of ICP-MS make it an indispensable tool in modern analytical laboratories.

Ensuring Longevity and Performance

Regular maintenance and timely replacement of components are essential for the longevity and performance of ICP-MS systems. Precision Glassblowing offers comprehensive maintenance services tailored to your specific needs. Our proactive approach helps prevent unexpected failures and ensures that your equipment remains in top condition.

A typical ICP-MS is composed of three basic parts:

- Sample Introduction System: As mentioned, this generally consists of a nebulizer and a spray chamber.

- Plasma Torch: This generates the plasma.

- Detection System: This includes the mass analyzer and detector.

Components Associated with ICP-MS

Regular maintenance of your ICP-MS system may require the replacement of one or more of these components which you can find on Precision Glassblowing’s handy online shop.

- Torch: Generates the plasma.

- Injector: Introduces the sample into the plasma.

- Sampler Cone: Extracts ions from the plasma.

- Skimmer Cone: Further refines the ion beam.

- Torch Tube: Houses the plasma torch.

- Spray Chamber: Removes larger droplets from the aerosol.

- Nebulizer: Converts the liquid sample into an aerosol.

- Gasket: Seals connections to prevent leaks.

- O-ring: Provides a seal between components.

- Humidifier: Maintains moisture levels to prevent sample drying.

- Pump: Moves the sample through the system.

Precision Glassblowing’s Role in ICP-MS Maintenance

Precision Glassblowing specializes in manufacturing and maintaining components essential for ICP-MS systems. Our expertise ensures that your equipment operates at peak performance, minimizing downtime and maximizing accuracy.

Torch Repair and Replacement

The plasma torch is a critical component of the ICP-MS system. Over time, torches can suffer from wear and tear, leading to decreased performance. Precision Glassblowing offers expert torch repair and replacement services. Our skilled technicians use high-quality materials to restore your torch to its optimal condition, ensuring consistent and reliable results.

Addressing Devitrification

Devitrification occurs when glass components in the ICP-MS system become cloudy or crystallized due to prolonged exposure to high temperatures. This can affect the efficiency and accuracy of the analysis. Precision Glassblowing provides solutions to address devitrification, including the use of specialized glass formulations and coatings that resist crystallization. Our team can also replace devitrified components to maintain the integrity of your system.

Customized Solutions

Every ICP-MS system is unique, and so are its maintenance requirements. Precision Glassblowing works closely with clients to develop customized maintenance plans. We consider factors such as usage patterns, environmental conditions, and specific analytical needs to create a plan that optimizes performance and minimizes downtime.

Expert Support

Our team of experts is always available to provide support and guidance. Whether you need advice on selecting the right components or assistance with troubleshooting, Precision Glassblowing is here to help. We pride ourselves on our commitment to customer satisfaction and our ability to deliver solutions that meet the highest standards of quality and reliability.

The Best in ICP-MS Support

Inductively coupled plasma mass spectrometry is a vital tool in modern analytical science. Precision Glassblowing plays a crucial role in supporting the maintenance and performance of ICP-MS systems. From New products to torch repair and replacement to addressing devitrification, our services ensure that your equipment operates at its best. Trust Precision Glassblowing for all your ICP-MS component needs and experience the difference that expert maintenance can make.

Do you have questions about ICP-MS? Visit our FAQs or Technical Information. And, there are several ways to contact Precision Glassblowing. Click here to pick one that works for you.