In the world of scientific and medical research, off-the-shelf isn’t always an option. Whether you are developing a new chemical process, refining an ICP (Inductively Coupled Plasma) application, or conducting high-pressure experiments, your equipment needs to be as unique as your hypothesis. At Precision Glassblowing, we specialize in bridging the gap between a complex concept and a functional glass tool. Our custom fabrication process is a collaborative journey that ensures accuracy, durability, and scientific success. Here is how we take your project from an initial idea to a final, high-performance product.

The Initial Custom Glass for Labs Consultation :: Understanding Your Goals

Every great piece of custom glass begins with a conversation. We don’t just ask for dimensions; we ask about the application.

- What temperatures will the glass encounter?

- What chemicals will it hold for analysis?

- Does it need to interface with specific ICP nebulizers or spray chambers instruments or consumables?

By talking through your specific needs, our team can identify potential challenges early and suggest the best materials (such as borosilicate or quartz) for the job.

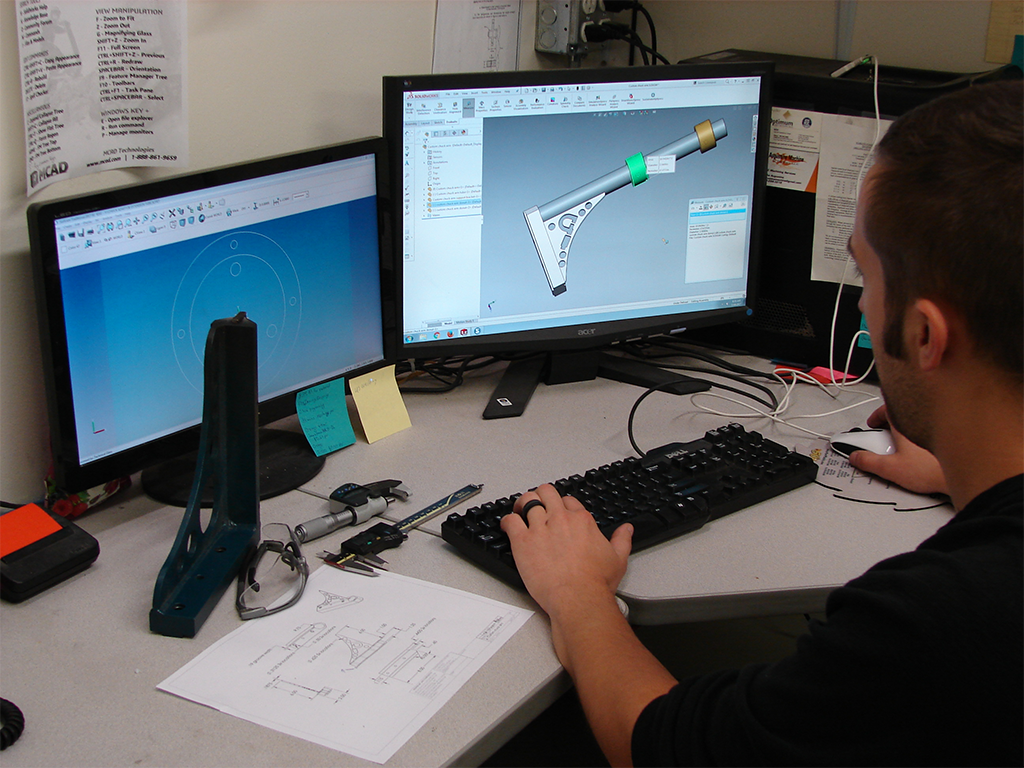

Conceptualization :: Generating the First Drawings

Once we understand the scope, our design team gets to work. We translate your requirements into technical blueprints. These initial drawings serve as the “ground truth”

for the project, detailing wall thickness, joint sizes, and tolerances.

Collaborative Revision :: Perfection Through Partnership

We believe the best results come from a feedback loop. We share the initial drawings with you to ensure every detail aligns with your setup. This is the stage where we:

- Refine port placements.

- Adjust volumes.

- Ensure compatibility with existing lab hardware instruments and hardware.

We continue to revise the drawings until you are 100% confident in the design.

Making the First Prototypes

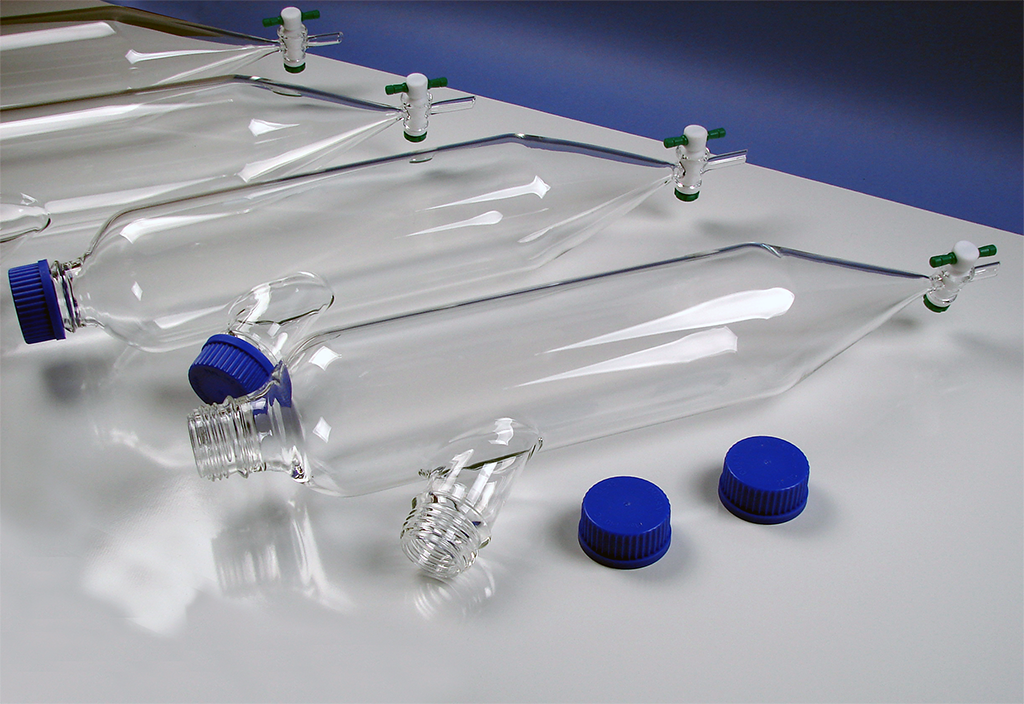

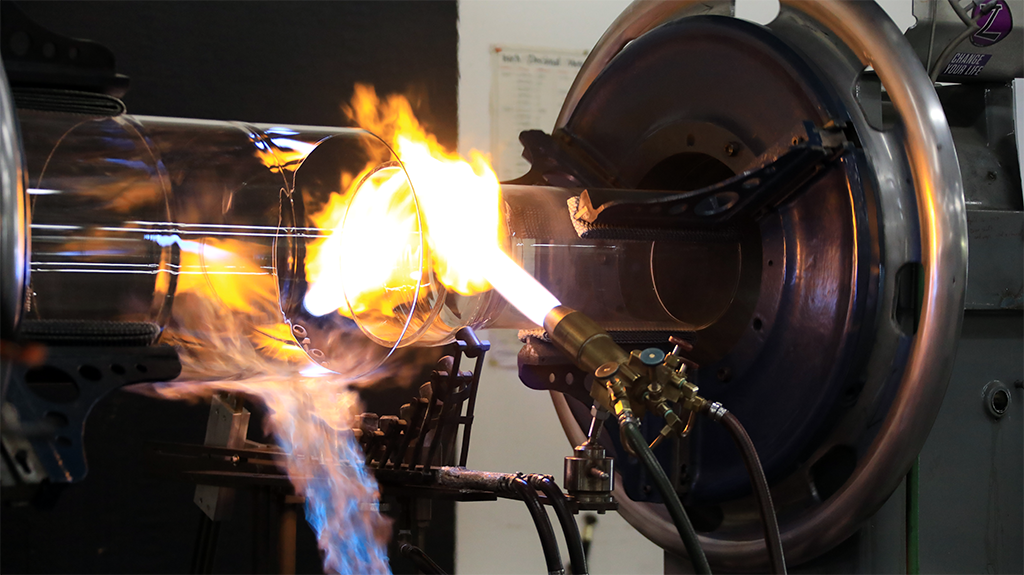

With a finalized drawing in hand, our master glassblowers move to the bench. This is where precision engineering meets artisanal skill. We produce a first-run prototype—a “living” version of the design. This stage allows us to test the physical integrity of the piece and ensures that the theoretical design translates perfectly into the physical world.

Testing and Refining

Rarely is scientific breakthrough a straight line, and custom glass is no different. Once the prototype is in hand, we evaluate it for any needed changes. If a fit is too tight or a flow rate needs adjusting, we make those refinements immediately. We don’t move to final production until the prototype meets every functional requirement of your lab.

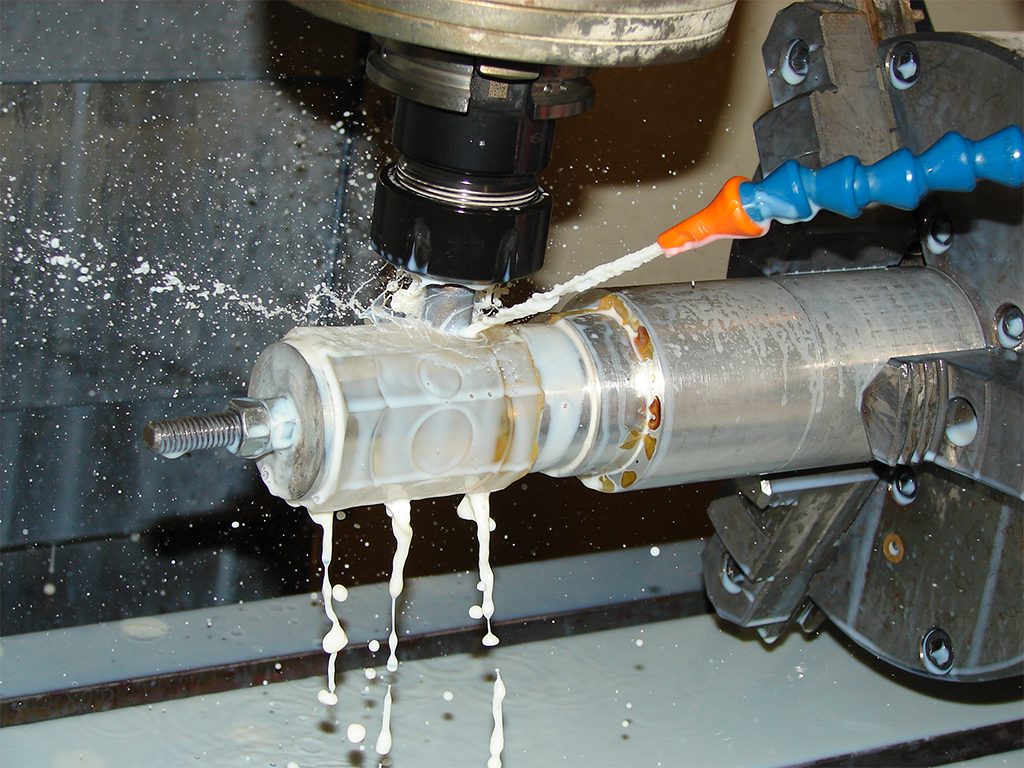

Final Production :: Delivering Success

The final product is more than just glass—it is a tool for discovery. Once the design is perfected, we move into final production, utilizing our state-of-the-art annealing ovensand machining equipment to ensure the glass is stress-free and built to last. The result? A custom solution that helps you get the job done, allowing you to focus onthe research that matters.

Ready to start your custom glass for labs project? Whether you have a rough sketch on a napkin or a full CAD file, our team is ready to help you bring it to life.